Streamlining Integration and Optimizing Control Panels: An OEM Case Study

Published:

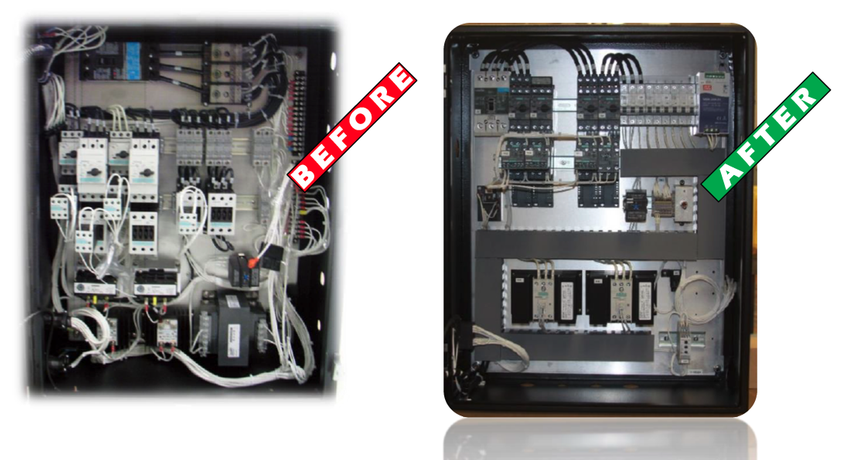

In today's fast-paced industrial landscape, Original Equipment Manufacturers (OEMs) face the constant challenge of staying competitive while meeting evolving customer demands. This case study explores how our team collaborated with OEM customers to refresh existing designs, optimize components, and streamline the integration process for their control panels. By leveraging cutting-edge technology and a modular approach, we successfully reduced hardware costs, simplified assembly and servicing, and minimized the time required for control panel installation.

Objectives

The primary objectives of this project were:

- Reduce components to achieve hardware cost savings

- Create a modular design for ease of assembly and servicing

- Apply the latest industry innovations and cutting-edge technology

- Streamline the integration process to save time and money

Approach

Design Refresh and Optimization

Our team began by thoroughly analyzing the existing control panel designs. We identified areas where components could be consolidated or replaced with more advanced, cost-effective alternatives. By leveraging the latest industry innovations, we optimized the design without compromising functionality or performance.

Modular Design Implementation

We developed a modular design approach to enhance the ease of assembly and servicing. Breaking down the control panel into smaller, interchangeable modules enabled faster assembly, simplified maintenance, and reduced downtime. This modular design also allowed for greater flexibility in customization, accommodating specific customer requirements with minimal modifications.

Streamlined Integration

One of the critical challenges OEMs face is the time-consuming process of integrating control panels into their equipment. To address this issue, we worked closely with our OEM customers to streamline the integration process. By providing comprehensive documentation, and plug-and-play connectivity, we significantly reduced the time and effort required for installation.

Results

The implementation of these strategies yielded impressive results for our OEM customers:

- Hardware cost savings of 15% achieved through component optimization

- Assembly time was reduced by 25% due to the modular design approach

- Integration time decreased by 30%, resulting in faster time-to-market

- Improved serviceability and reduced downtime, leading to enhanced customer satisfaction

Conclusion

This case study demonstrates the power of collaboration, innovation, and a customer-centric approach to driving OEM success. By refreshing existing designs, optimizing components, and streamlining the integration process, we enabled our customers to achieve significant cost savings, improved efficiency, and enhanced competitiveness in their respective markets. As technology evolves, we remain committed to partnering with OEMs to deliver cutting-edge solutions that meet their unique challenges and drive long-term success.

Have questions? Conact our sales team for more information.

OMNI CONTROL TECHNOLOGY INC

1 Main St #4, Whitinsville, MA 01588 - TEL: 1-508-234-9121

ISO 9001:2015

ISO 14001:2015

UL508A

UL698A

Copyright 2021 © Omni Control Technology | All Rights Reserved.